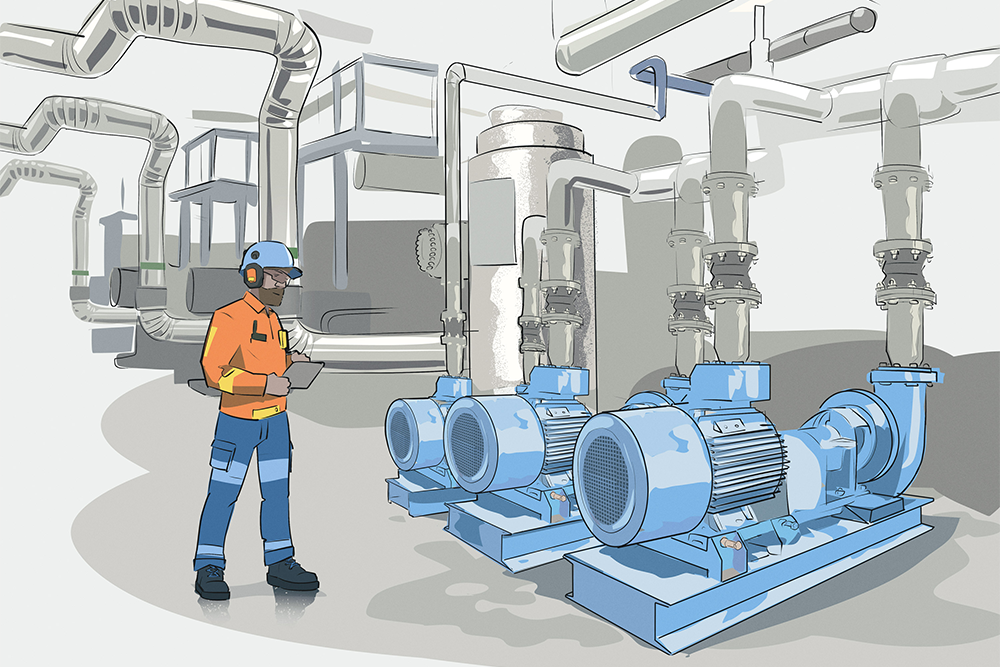

Monitoring of industrial equipment

Initial situation: machinery mostly outdated and not networked with each other

Reliable monitoring of machinery and equipment is a must for municipal utilities and energy suppliers, just as it is for any manufacturing plant – but it is particularly relevant for existing systems that are not networked, as energy consumption is usually not transparent here. In addition, machine failures cannot be predicted, which often makes maintenance inflexible. This can result in long unplanned machine downtimes and thus also high costs and time losses.

Retrofitting existing systems with intelligent sensor technology

With the help of IoT sensors and LoRaWAN®, all existing plants can be retrofitted and adapted for comprehensive energy consumption monitoring. Using plug-and-play sensors, this conversion is also simple and non-invasive. All relevant data, such as temperature or the number of operating hours, are recorded centrally and transmitted via LoRaWAN® to the B.One element iot platform for further processing.

Predictive maintenance using IoT sensors

- Time and cost savings

- Unplanned downtimes are avoided

- Transparent and data-based basis for decision-making

- Increase in process efficiency

The data collected also enable predictive maintenance of the machines and alerting.